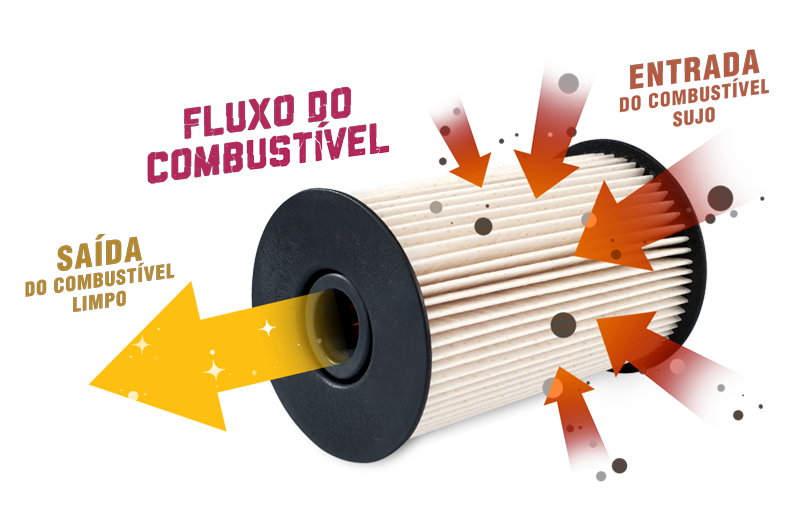

The Fuel Filter is the component responsible for retaining impurities in the fuel accumulated in the vehicle’s tank, preventing them from reaching the injection pump, injection nozzles and injection units (electronic vehicles).

The filter is usually located between the fuel tank and the engine. There are also models called In-Tank, which are installed inside the tank.

Wega is a partner of the Brazilian Filter Association (ABRAFILTROS) in the Recycling and Conscious Disposal of Used Filters program, participating in the actions and decisions of the body in its concern for the environment.

State-of-the-art fuel filter technology

Wega Tip: Always lubricate the nozzles of the Fuel Filter when removing it; pay attention to the arrow indicating the correct mounting of the filter.

Wega Motors strictly adheres to all technical specifications when developing its products, in accordance with the designs of national and imported vehicle manufacturers.

Wega Motors Fuel Filter, innovating more and more with cutting-edge technology.

We recommend following the guidelines in the vehicle manufacturer’s manual. In general, we recommend changing the fuel filter every 10,000 km.

Due to variations in diesel quality at different service stations, you need to monitor performance (consumption / loss of power) and change it when necessary.

Without changing it at the right time, the fuel filter becomes saturated and can compromise the fuel supply system. This can impair performance and increase consumption, damaging the fuel pump, nozzles, injector units and even causing the vehicle to come to a complete standstill.

Never skip regular revisions.

Os filtros de combustível oferecem uma série de vantagens no funcionamento de um veículo

Always lubricate the gasket with lubricating oil and top up the filter level with clean diesel oil to prevent air from entering the system. Apply the correct torque when assembling. For “Filter Refill” models, lubricate the o-ring and apply the tightening described on the reservoir cover.

The new technologies incorporated into the Wega Motors Fuel Filter range meet the strict design requirements for engines with electronic fuel injection and guarantee safety during filtration. Get to know some of the varieties:

InTank model, Pre-filter, Plastic filter, Refill filter, Separator filter, Metal filter.

Wega Motors has the most complete range of fuel filters on the market, whatever the type of fuel used, with applications for passenger cars, SUVs, pick-ups, motorcycles, trucks, buses, tractors and agricultural machinery – both domestic and imported.

All are developed with high technology in various formats, according to each application and following the original design of the engines.

In Tank filters, for example, form a single unit between the housing and the filter element, making them a complete solution. The filter is coupled to the fuel pump, which is housed inside the tank, hence the name “InTank”.

Wega Motors Fuel Filters have state-of-the-art technology, which can be seen in the following items:

Externally sealed by roto-fusion, to withstand the pressure required by the fuel pump.

Fixing of the paper element: in the filter element, the paper is fused directly to the plastic cover, guaranteeing perfect fuel filtration; no metal parts and environmentally friendly.

Specific pleated paper that meets the requirements of different types of fuel, guaranteeing efficiency, performance and a perfect seal.

Housing made of polypropylene, with a wall thickness of 2.5mm, nylon fibers and special additives that increase the filter’s performance and safety.

Wega Motors Ecological Fuel Filters are developed in line with global trends and governmental requirements, in the search for technological innovations in automobiles and automotive products that contribute to the sustainability of the planet.

The eco-filter is constructed using only a pleated filter element, which is fused directly to the plastic cover (no need to use chemical glues or adhesives), developed using materials of the highest quality and adapted to the designs and engines that use this technology.

They dispense with the use of various raw materials and components such as: sheet metal housing, metal cover, valve and adhesives that would otherwise be discarded in nature.

It can be easily pressed, making it possible to completely reuse the lubricating oil or fuel oil impregnated in the filter element. It is then incinerated without contaminating the soil or emitting toxic gases into the environment.

Download our app and explore our complete portfolio, full of spark plugs and automotive filters. A 100% updated catalog, featuring the latest releases.

Apple Store

Google Play

Apple Store

Google Play

Itajaí Unit – Headquarters

Avenida Mário Uriarte, 1060 – Cordeiros – Itajaí/SC

ZIP Code: 88311-740

São Paulo Unit (Sales and Technical Support)

R. Bom Pastor, 2100 – Room 606 – Ipiranga – São Paulo/SP

ZIP Code: 04203-002

Factory in Argentina

Calle Bolívar, 3441 – Lomas Del Mirador – Buenos Aires

ZIP Code: B1752AJM