The Cooling System Filter has two functions: to trap impurities and to additivate the cooling system, as the filter contains additives in the form of tablets that dissolve in contact with water.

Follow the recommendations in the vehicle manufacturer’s manual for changing the cooling system filter. Wega recommends changing it every 40,000 to 60,000 km and also periodically checking the water level in the system and the mixture of water and monoethylene glycol.

The Cooling System Filter should be changed every time the cooling system is serviced, i.e. if you have changed the water in the system, you should change the filter and top it up with the monoethylene glycol additive.

By doing this, your cooling system and engine will be better protected, and your truck, bus and equipment will have a longer service life.

Remember: change the filter every time you change the fluid in the cooling system.

Preventive maintenance of the Cooling System Filter prevents problems such as:

Lubricate the filter gasket with clean oil, apply the correct torque and always change the liquid (water and monoethylene glycol) in the correct mixing ratio.

Need to find the exact filter model for your needs? Click here for our Online Search.

mos que a troca deve ser feita entre 40 e 60 mil km rodados. Lembrando que é fundamental verificar regularmente o nível e a qualidade do líquido de arrefecimento, bem como substituir o filtro sempre que o líquido for trocado.

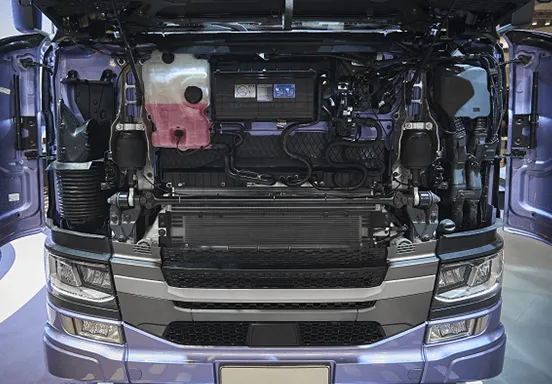

The cooling system filter is used to retain impurities generated by the engine system itself, i.e. the cooling system generates impurities. This is a consequence of the engine heating up and cooling down, which creates wear and tear in the block, more precisely in the water galleries. This impurity or residue generated is rust (oxidation), which ends up leaching out of the galleries and is carried to other parts of the system, potentially damaging the water pump, hoses and even the engine itself.

That’s why the filter needs to be in top condition to retain all these impurities generated and carried by the galleries. The filter must retain the contaminants, allowing only the water and additive to pass through to protect and care for the system.

Liquid (a mixture of water and monoethylene glycol) contaminated by rust generated in the cooling system can clog the galleries in the engine block, causing overheating, increased pressure and even engine failure.

Download our app and explore our complete portfolio, full of spark plugs and automotive filters. A 100% updated catalog, featuring the latest releases.

Apple Store

Google Play

Apple Store

Google Play

Itajaí Unit – Headquarters

Avenida Mário Uriarte, 1060 – Cordeiros – Itajaí/SC

ZIP Code: 88311-740

São Paulo Unit (Sales and Technical Support)

R. Bom Pastor, 2100 – Room 606 – Ipiranga – São Paulo/SP

ZIP Code: 04203-002

Factory in Argentina

Calle Bolívar, 3441 – Lomas Del Mirador – Buenos Aires

ZIP Code: B1752AJM